Milorganite®: Pioneering Wastewater Recycling and Environmental Stewardship Since 1926

The production of Milorganite® fertilizer is one of the nation’s oldest recycling efforts. Since 1926, Milwaukee has safely recycled the nutrient-rich microorganisms from the Milwaukee Metropolitan Sewerage District’s (MMSD) water reclamation process into Milorganite's slow-release nitrogen fertilizer.

Headquartered in Milwaukee, Wisconsin, Milorganite is manufactured and marketed by MMSD, a regional government agency that provides water reclamation and flood management to the Greater Milwaukee area, servicing over one million customers in 29 communities. In this blog, learn about the past, present, and future of Milorganite and MMSD’s dedication to protecting public health and the environment.

Milwaukee’s Rivers: A Legacy of Toxic Pollution

The origins of the MMSD date back to 1913, with the establishment of the Sewerage Commission of the City of Milwaukee to build a sewerage system to address how sewerage was disposed of. It was common practice then to allow raw sewerage and industrial waste to flow directly into rivers and Lake Michigan, creating putrid conditions and risking public health, such as in 1909 during a deadly typhoid scare.

The source of drinking water, Lake Michigan, was contaminated.

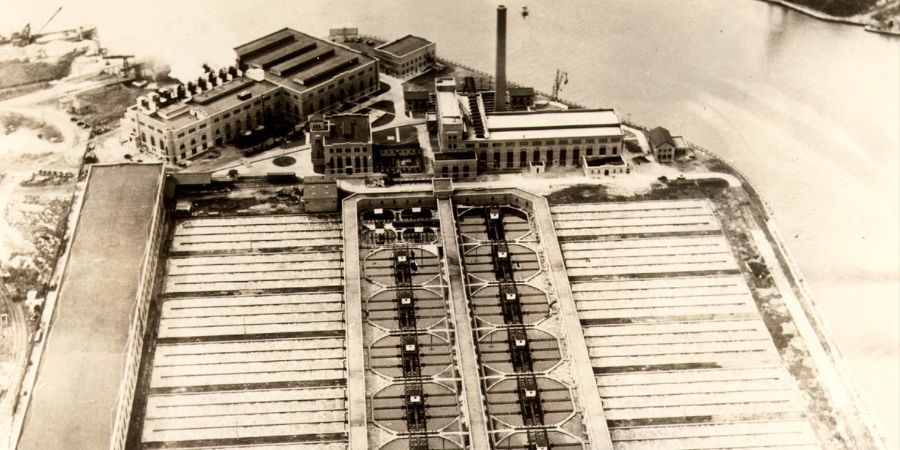

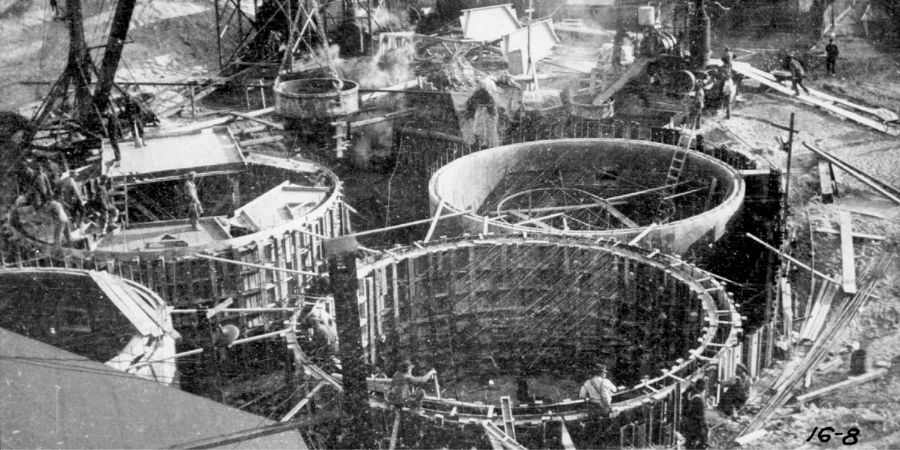

In 1914, the Commission adopted a new approach being developed in Europe for treating wastewater called the activated sludge (biosolids) method, which used microorganisms to digest the nutrients found in the wastewater. The pilot facility was built in Milwaukee and eventually replaced in 1925 by the Jones Island Water Reclamation Facility.

Turning Wastewater into a Sustainable Fertilizer

Milorganite was born out of the demand to improve water quality, one of the scarcest resources on the planet.

Reclaiming wastewater using the biosolids process remains as cutting edge today as it was in the early 1900s. Using natural processes, microorganisms consume organic matter and its many nutrients. But there was a problem with what to do with the remaining resulting material—the abundant volume of microbes.

Rather than disposing of the plentiful, nutrient-rich microbes into landfills, Milwaukee’s answer was to produce Milorganite, a slow-release nitrogen fertilizer. Over 10 billion pounds of waste has been diverted from landfills into Milorganite.

How is Milorganite® Fertilizer Made?

Once in a Generation Opportunity: Restoring Milwaukee’s Rivers

The Milwaukee Estuary is where the Milwaukee, Menomonee and Kinnickinnic Rivers merge and empty into Lake Michigan remains one of the most environmentally degraded sites on the Great Lakes. Historically, Milwaukee was self-acclaimed as the “Machine Shop of the World,” but it came at a cost.

Milwaukee River downtown Milwaukee present day.

Restoring the Milwaukee Estuary is a generational opportunity—the first generation in history that will leave Milwaukee’s rivers and Lake Michigan in better condition than it was found.

Launched in 2023, the restoration of the Milwaukee Estuary Area of Concern (AOC) is the largest-ever clean-up under the United States Environmental Protection Agency’s Great Lakes Restoration Initiative and the Great Lakes Legacy Act. This is also the largest single clean-up initiative on the Great Lakes in history, with the fastest timeline and the largest number of partners in the region’s history.

Kevin Shafer, Executive Director at MMSD shared, “Now the hard work begins by removing contaminated sediments, improving habitat, and making the Milwaukee region a safer, cleaner place to live.”

To learn about the MMSD Milwaukee Estuary AOC projects and all of the projects underway, visit the Waterway Restoration Partnership website.

Environmental stewardship and protecting public health remain top priorities at MMSD and Milorganite, and producing a safe and effective slow-release nitrogen fertilizer for our customers.